Battery Cable AWG Sizing

Share

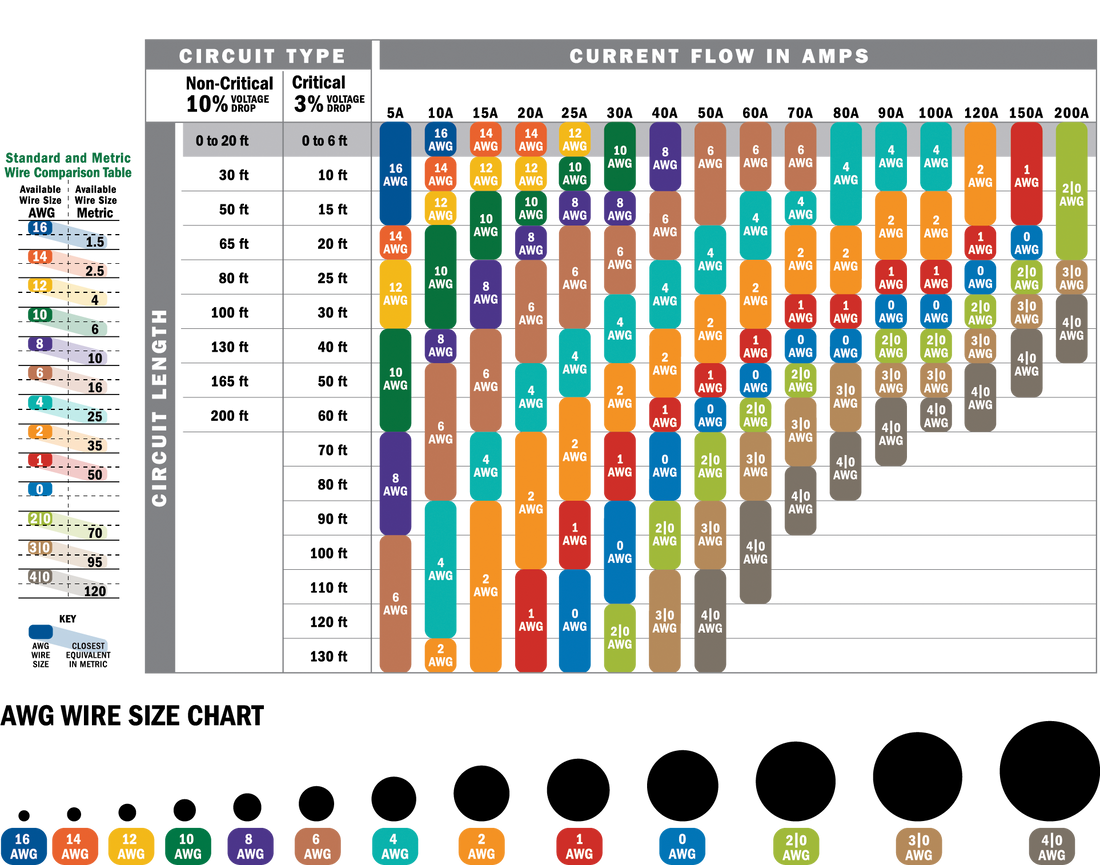

Choosing the right wire size is important, because if you choose a wire too small it can get very hot and possibly start a fire. When in doubt it makes sense to use a higher temperature rated cable, like up to 105 deg C.

Since the goal is to minimize resistance in the wires, set a few guidelines to avoid an excessive drop in voltage. Depending on where the conductor is in the circuit, the voltage drop due to conductor resistance should be calculated and appropriate for each circuit.

When choosing the correct conductor, you must determine the maximum current in the circuit, the size of the fuses or breakers, the ambient temperature, and the material type of the conductor and insulation. With this information, you can make a calculated decision concerning the proper gauge and type of wire. Keep in mind that if you plan on grouping many conductors inside of conduit or in an enclosed wire tray, this will change the ambient temperature. It is also important to make sure that the terminal connections and end connectors are not the highest points of resistance. Some equipment might have a required torque value on the fasteners in order to minimize unintended resistance.

Follow these instructions to choose the current wire gauge:

- Max Current: Identify the max current (Amps) of your DC system, typically this would be the input DC current on your charger plus any other DC loads.

- Length: Measure the length (in feet) of the wire run accounting for bend angles. Typically this would be from the battery terminals to the input on the charger. Note that the length shown in the chart is the roundtrip distance, so double the length of one wire.

-

Circuit Type: Select the type of circuit and the allowable drop in voltage based on the use case.

- Critical circuits (3% allowable voltage drop) include: Main Panel feeders, Electronics, Safety Equipment

- Non-critical circuits (10% allowable voltage drop) include: General lighting, General appliances

1 comment

I would appreciate your help. Can you tell me where I can purchase a Blue Sea or equivalent cable chart? Best Regards Arthur Wills